SCF CO2 Extracted Oils & Oleoresins

SCF CO

2 Extraction is a green separation process by which all the natural plant products can be extracted. These Extracts are impurity free product, pure, free from any solvent residue, microbial contamination, heavy metals etc. in comparison to other conventional extraction process. This process is carried out in an inert atmosphere, hence enhanced shelf life. In this process, extraction is carried out at low temperature, hence extracts retains the natural freshness, delicacy, truly preserves the aroma & flavour present in the raw material and more importantly the synergistic bio-availability of natural molecules

know more.

Essential Oils

Raw Plant Material, consisting of the flowers, leaves, wood, bark, roots, seeds, or peel, is put into an alembic or distillers over water. As the water is heated, the steam passes through the plant material, vaporizing the volatile compounds. The vapors flow through a coil, where they condense back to liquid, which is then collected in the receiving vessel. The recondensed water is referred to as a Hydrosol, herbal distillate or water essence, which may be sold as another fragrant product.

Spice Oleoresins & Extracts

Spice oleoresins & extracts are obtained by solvent extraction of the powdered dried spices with a suitable solvent and subsequent removal of solvent. The volatile oil called essential oil is distilled out from the grounded spices. The wet powdered spice free from volatiles are dried and then extracted with the solvent to remove the fixed oil & resinous material. The solvent is removed by the solvent recovery system and the extracts are grinded, sieved & the suitably packed.

Herbal Extracts

Once the best herbs are selected, they are cleaned, prepared & grinded according to a protocol customized for that herb. The prepared herbs are then enters into extractors & distillers to obtain the herbal extracts with suitable solvents or water and then solvent is removed through solvent recovery system. Extracted wet powdered herbs are dried and then grinded, sieved & the dried powder is suitably packed.

Carrier Oils

Best Carrier Oils are extracted by Cold Pressed or cold expeller process. This indicates that oil has been extracted by pressing the fatty portions of the botanical without the use of added heat. The process can still generate heat due to friction, but cold expeller pressed oils are processed under conditions that keep the heat to a minimum. The seeds or nuts are placed in a horizontal press with a rotating screw known as an ‘expeller” and the oil is literally squeezed out. The oil is then filtered and sold as a finished product.

SUPERCRITICAL FLUID EXTRACTION (SCFE) TECHNOLOGY

The technology is being utilized for the manufacturing of various

essential oils, oleoresins and herbal extracts, natural colours, Decaffeination of coffee & liquid fractionation. These products are well sought after for applications in Flavors, Fragrances, Medicines, Food, Cosmetics, Nutraceuticals and Aromatherapy.

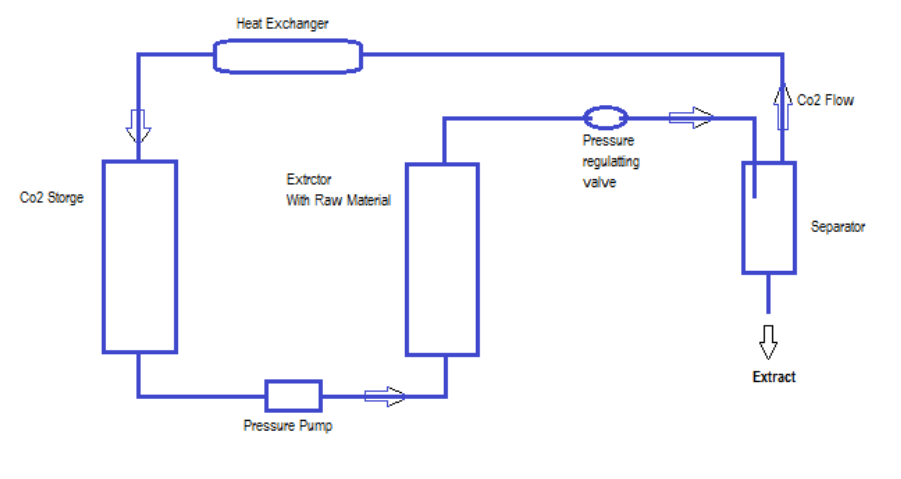

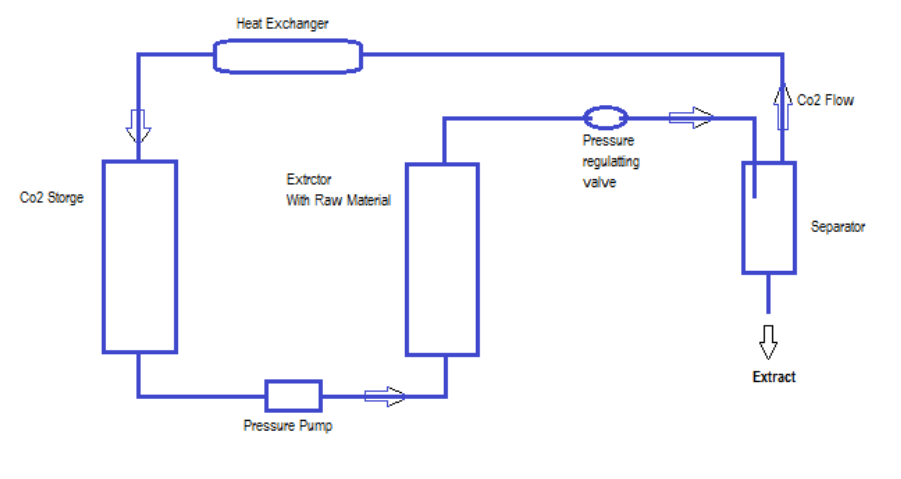

PROCESS

- SCFE is a two-step process which uses dense gas as a solvent e.g. carbon dioxide (CO2) for extraction, above its critical temperature (31º C) and critical pressure (74 kg/cm²).

- The feed, generally ground solid /liquid, is charged into the extractor.

- Supercritical CO2 is fed to the extractor through a high pressure pump (100-500 kg/cm²).

- The extract laden CO2 is sent to a separator (60-120 kg/cm²) via a pressure reduction valve.

- At reduced temperature and pressure conditions, the extract precipitates out in the separator.

- The extract free CO2 stream, leaving the separator is then recycled to the extractor.

- In the case of liquid feed, the extractor is modified into a column through which feed and the supercritical CO2 is fed either co- currently or concurrently.

Advantages of SCFE:

- No harmful residue.

- No Hydrolysis or destruction of temperature sensitive active ingredients.

- Products contain lower levels of monoterpene hydrocarbons.

- Products obtained that is closest to the aroma and other properties of the original botanical material.

- Longer shelf life extracts.

- Dissolving power of the SCO2 is controlled by pressure and/or temperature

- CO2 is easily recoverable due to its volatility

- High boiling components are extracted at relatively low temperatures

- Thermally labile compounds can be extracted with minimal damage m

- Free from any type of environmental pollution.

Our SCFE Products are used by various end users like

- Natural Flavors for Pharmaceutical products and Food industry

- Purify ingredients for Herbal Medicines and Cosmetics

- Excellent Fragrance for Perfumery & Aromatherapy formulation

- Unaltered ingredients for Nutraceuticals and Functional Foods

- For antioxidative and antimicrobial constituents

- Anti-inflammatory constituents, Anticancer alkaloids, Anti-carcinogenic polyphenols

- Therapeutic oils and fatty acids

- Flavonoids and carotenoids

- Decaffeination of coffee

- Natural antioxidants extraction like β Carotene

- Natural food colours

Why should one use CO2 Extracts when they are Expensive?

- Nearest to natural botanical raw materials!

- No solvent residues!

- No Heavy metals!

- No microbial contamination!

- No decomposition, hydrolysis or hydrolysis products!

- No polar substances!

- Better stability in the formulation, longer shelf life for end products

- Reduced consumption resulting in economy benefits of 15-25% in final application!